DTF Gangsheet Builder has emerged as a pivotal tool for designers and production teams navigating the world of direct-to-film printing, offering a robust platform that combines intelligent layout, reliable color management, and seamless integration with existing design pipelines. In today’s fast-paced apparel and textile markets, speed without sacrificing quality is essential, and this solution optimizes gangsheet layout to maximize efficiency, reduce waste, and ensure consistent results across large batches—an essential advantage for busy production floors. By automatically arranging multiple designs on a single sheet, it reduces material waste and ink usage, helping to speed up batch printing, improve throughput, and simplify the handoff from design to RIP software while preserving color fidelity. From initial design import to final export, this tool streamlines workflows so teams produce production-ready sheets with minimal friction, offers clear, repeatable presets, supports export formats compatible with popular DTF printer pipelines, and even provides DTF heat transfer tips and design tips for DTF to maximize downstream success. Whether you are a seasoned printer or a designer transitioning to production, adopting this approach can save time, reduce costs, and elevate outcomes in DTF printing.

Viewed through an expanded lens, this concept behaves like a multi-design layout engine that bundles several graphics onto one printing surface, enabling faster textile runs and tighter cost control. Practically speaking, people often call it a gangsheet creator or production planner, harmonizing artwork files, color profiles, and printer pipelines to deliver consistent results across batches. By emphasizing space optimization, bleed management, and precise alignment, the tool supports scalable workflows that align creative intent with manufacturing realities. For teams adopting this approach, the focus shifts from single proofs to repeatable processes, aided by templates, asset libraries, and automated checks that minimize rework and improve throughput. In short, the aim is to translate artistic ideas into production-ready sheets that maintain color fidelity and efficient material use, a shared goal among designers, print shops, and textile houses.

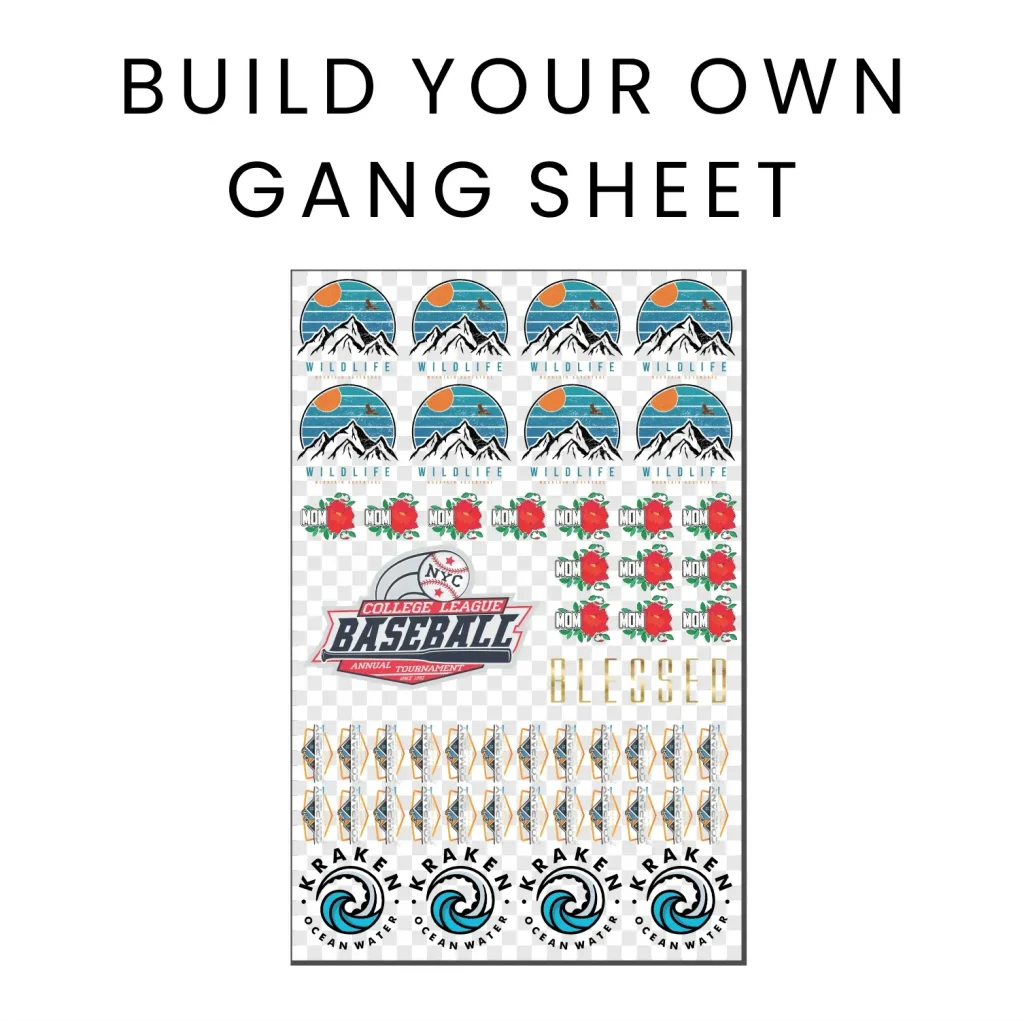

What is a DTF Gangsheet Builder and Why It Matters for DTF Printing and Gangsheet Layout

A DTF Gangsheet Builder is a software solution that automates and optimizes the creation of gangsheets for direct-to-film (DTF) printing. It takes multiple artwork files and arranges them into a single print-ready layout, preserving color integrity while minimizing material usage. Key capabilities include automatic tiling, intelligent spacing, bleed and safe zones, and export formats that align with your DTF printer pipeline.

For designers, this tool accelerates the move from single-file proofs to production-ready gangsheet layouts, helping ensure consistency across batches. For production teams, it reduces setup time and lowers per-unit costs, enabling scalable runs without sacrificing output quality.

Core Features That Drive Value for Designers in DTF Gangsheet Layouts

A robust DTF Gangsheet Builder typically offers features that support design accuracy and production readiness. Core capabilities include automatic gangsheet layout and tiling, which positions multiple designs on a sheet to optimize space and reduce waste—a boon for batch printing.

Additional features like color management and profiling, bleed and safe-zone handling, template libraries, import and export options, batch processing, previews, and workflow integrations help ensure color fidelity and predictable results on the final DTF print.

Maximizing Efficiency in Batch Printing with DTF Gangsheet Layouts

Effective batch printing relies on upfront planning of gangsheet layouts. Outline how many designs, their sizes, and any color constraints before layout to let the builder optimize space and minimize wastage.

Use presets for common jobs, validate with proofs, and group designs by color families or ink usage to reduce color changes and maintenance downtime. These practices improve throughput while maintaining consistent output.

Design Tips for DTF: Creating Production-Ready Assets for Gangsheet Print

Designers should prioritize legibility and detail within the sheet constraints. Use scalable vector art when possible, align layers to a grid, and plan color separations to simplify the DTF workflow.

These guidelines align with design tips for DTF to ensure assets translate cleanly when tiled on a gangsheet, and metadata or notes can help operators reproduce the same result across batches.

Color Management, Proofing, and Quality in DTF Printing

Calibrate color across monitors and printers, use ICC profiles, and validate design previews to ensure color fidelity on the final DTF print.

DTF heat transfer tips include confirming transfer temperatures, times, peel methods, and media compatibility. Running small proofs helps catch issues before large batch runs and allows color and layout adjustments as needed.

From Proof to Production: Export, Validation, and Workflow Integration for Reliable DTF Heat Transfer

A well-designed workflow moves from proof to production with validated gangsheet exports, ensuring file formats align with RIP software and printer pipelines. Clear export settings and validation checks reduce surprises in the press room.

Establish standard operating procedures, maintain asset libraries, and align heat transfer parameters across batch runs to ensure reliable results in DTF heat transfer applications. This cohesive pipeline speeds up production while preserving quality.

Frequently Asked Questions

What is the DTF Gangsheet Builder and why does it matter for DTF printing?

The DTF Gangsheet Builder is a software solution designed to automate and optimize the creation of gangsheets for DTF printing. It automatically tiles multiple designs on a single sheet, preserves color integrity, and minimizes material usage while speeding production. Typical features include automatic gangsheet layout and tiling, bleed and safe-zone handling, and export formats compatible with your printer pipeline. For designers, it speeds the move from proofs to production-ready layouts; for production teams, it reduces setup times and lowers per-unit costs, enabling scalable, consistent DTF outputs.

How does gangsheet layout benefit batch printing in DTF projects?

A well-implemented gangsheet layout places multiple designs on one sheet, maximizing space and minimizing waste. This directly benefits batch printing by reducing material usage, speeding setup, and enabling consistent, high-throughput runs. By managing spacing, margins, and tile placement, the gangsheet layout helps keep color and alignment stable across many prints in a batch.

What design tips for DTF should I apply when using the DTF Gangsheet Builder?

When using the DTF Gangsheet Builder, apply these design tips for DTF: prioritize legibility and detail within the sheet; use vector artwork where possible for clean scaling; plan color separations to simplify color management; mind the sheet orientation and alignment to maintain production speed; include metadata and notes about color profiles and transfer parameters to streamline setup.

Which features should I prioritize in a DTF Gangsheet Builder to ensure production-ready results?

Prioritize features that bridge design and production: automatic gangsheet layout and tiling for efficient packing, robust color management and ICC profile support, bleed and safe-zone handling, a template library with presets, reliable import/export options, batch processing and queue management, and strong preview/validation tools. Also look for seamless workflow integration with your design tools and printer pipeline to ensure production-ready gangsheets.

How can I achieve color accuracy for batch printing when using the DTF Gangsheet Builder?

To achieve color accuracy in batch printing with the DTF Gangsheet Builder, implement a solid color management workflow: calibrate monitors and printers, use consistent ICC profiles, and standardize media. Validate layouts with real-time previews and proofing, and run test sheets to confirm color fidelity across designs in a batch. For added guidance, follow DTF heat transfer tips by aligning transfer temperatures, times, and peel methods with your chosen media.

What common pitfalls should I avoid with DTF Gangsheet Builder workflows and how can I prevent them?

Common pitfalls include overcrowding designs on a sheet, resulting in misalignment and poor print quality; inconsistent color management across designs; ignoring bleed and safe zones; poor file organization and naming; and skipping proofing before printing. Prevent these by leaving proper margins, using a unified color profile, adhering to bleed/safe zone guidelines, maintaining organized asset libraries, and running thorough previews and proofs before batch printing.

| Topic | Key Points |

|---|---|

| What is a DTF Gangsheet Builder? | Software that automates and optimizes the creation of gangsheets for DTF printing by arranging artwork into a single print-ready layout while preserving color integrity and minimizing material usage; includes features like automatic tiling, spacing, bleed and safe zones, and export formats. |

| Why it matters | Speeds production, reduces waste, lowers per-unit costs, ensures consistency across batches, and scales up projects without sacrificing quality. |

| Core Features | Automatic layout/tiling, color management and profiling, bleed/margin/safe-zone handling, template library and presets, import/export options, batch processing and queue, preview/validation, and workflow integration. |

| Tips for Getting the Most | Plan layout, optimize assets, leverage presets, validate with previews, consider batch economics, establish naming conventions, and align output with post-print steps. |

| Design Tips | Prioritize legibility, use vector artwork where possible, plan color separations, mind print dimensions and orientation, and include metadata/notes in files. |

| Best Practices | Calibrate color and media, validate ink usage and speed for batches, create a robust review loop, maintain organized asset libraries, and document SOPs. |

| Real-World Workflows | Example: 12 designs on one gangsheet with standard sheet size, bleed/safe zones, color profiles, batch printing, and repeatable presets for campaigns. |

| Common Pitfalls | Overcrowding, inconsistent color management, ignoring bleed and safe zones, poor file organization, and relying on defaults without proofing. |