UV DTF transfers offer a powerful way for brands to scale custom gear printing with bold color and quick turnaround. As UV DTF printing processes mature, DTF transfers in this format deliver vibrant visuals that hold up through washes, making them ideal for apparel branding across events, teams, and retail merch. Because they work well on a wide range of fabrics, these transfers empower scalable textile printing while keeping margins favorable for small and large runs. The technology supports low minimums and fast prototyping, enabling designers and marketing teams to explore new designs without sacrificing quality for every garment. From artwork to finished pieces, UV DTF transfers underpin reliable, repeatable processes for brands pursuing consistent visuals and growth in apparel branding.

In alternative framing, ultraviolet-curable film transfers describe the same process—where inks are cured instantly under UV light to create sharp, durable images. This approach maps to terms such as direct-to-film decoration and DTF-like transfers, which highlight versatility for fabrics and blends. Think in terms of UV-LED cured print-on-film technology and the broader idea of apparel branding realized through scalable textile printing. The emphasis remains the same: fast, durable results, strong color fidelity, and a quick path from design to distribution for on-demand or large runs.

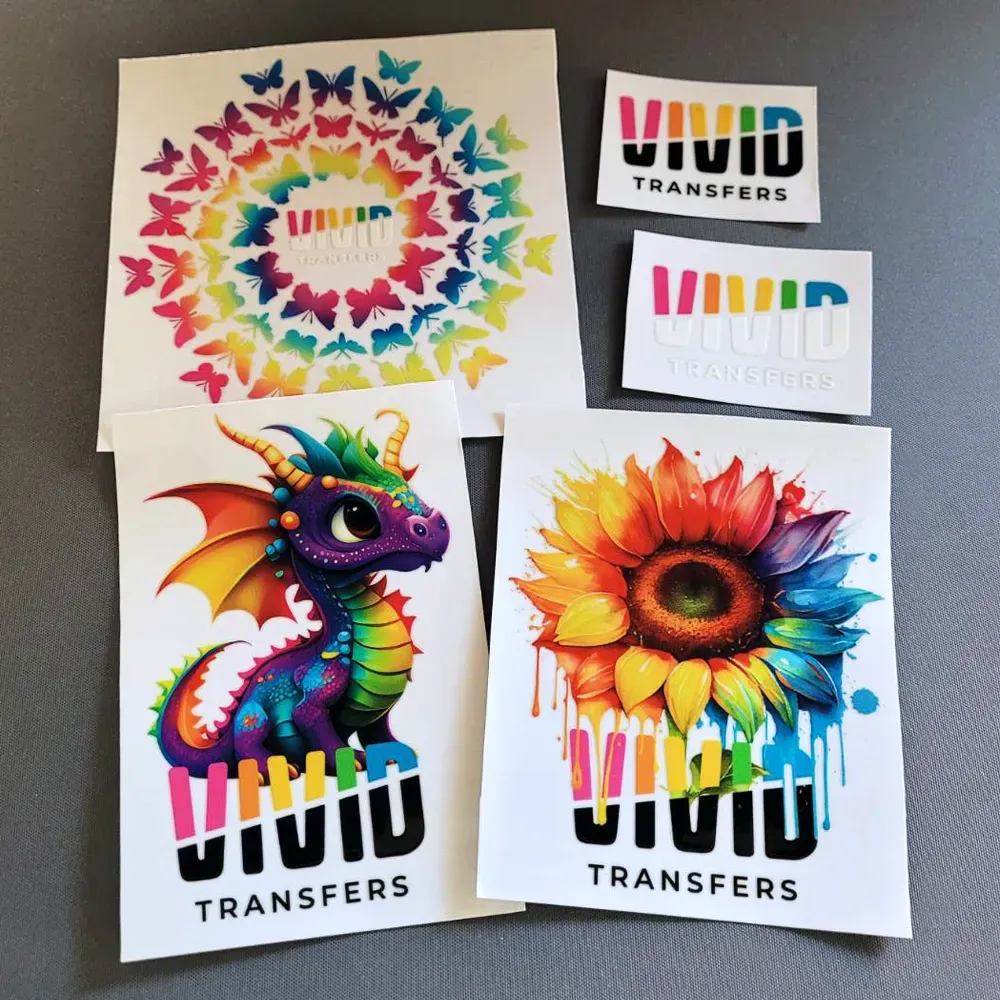

UV DTF transfers: Driving scalable custom gear printing with vibrant results

UV DTF transfers represent a transformative approach to apparel branding by combining UV-curable inks with direct-to-film workflows. This method aligns closely with the goals of custom gear printing, enabling bold, photorealistic imagery on a wide range of fabrics and surfaces. By leveraging UV DTF printing, brands can produce small batches or large runs without compromising color accuracy or durability, making it a natural fit for scalable textile printing initiatives and versatile merch programs.

For teams building an in-house or outsourced apparel line, UV DTF transfers provide a fast, reliable path from concept to customer. The process supports rapid prototyping, minimal start-up costs, and streamlined production, all while preserving the integrity of logos and artwork across diverse substrates. This makes it easier to maintain consistent branding across event gear, team apparel, retail merch, and corporate swag—key elements of a cohesive apparel branding strategy.

Maximizing color fidelity with UV DTF printing for brand-rich apparel branding

Color fidelity is a core advantage of UV DTF printing. UV inks deliver a broad color gamut with clean edges and smooth gradients, which is essential for logos, photographic art, and intricate brand elements. When paired with precise color management and proofing, brands can translate complex artwork into apparel that remains faithful to the original design, reinforcing consistent apparel branding across product lines.

The workflow supports reliable reproduction across multiple fabric types—cotton, blends, and some synthetics—while maintaining a soft hand-feel and durable finish. By integrating color standards, proofing steps, and substrate testing into your process, you can minimize surprises at print time and preserve the visual impact of your designs on all pieces within a scalable textile printing program.

UV DTF transfers vs traditional methods: choosing the right path for small runs

For small batch runs, UV DTF transfers offer a compelling alternative to traditional screen printing and other heat transfer methods. The setup is quicker, minimums are often lower, and you can iterate designs without large upfront tooling costs. This makes DT F transfers an attractive option for prototype collections, limited editions, and on-demand apparel branding campaigns.

Durability and wash resilience are strong with properly cured UV DTF transfers, and the ability to handle mixed materials reduces the need for multiple production lines. When evaluating options, consider not only unit cost but also turnaround time, color fidelity, and maintenance requirements—factors that collectively influence scalability and long-term profitability in a multi-product line.

Scaling a UV DTF program: operational strategies for custom gear printing

A scalable UV DTF program hinges on efficient batch planning, template-driven workflows, and robust supplier networks. Grouping similar designs and garments can maximize press time and reduce setup changes, while templates for placements and color palettes ensure brand consistency across products. This aligns with scalable textile printing goals by enabling predictable throughput as volumes grow.

Investing in automation where feasible—such as automated transfer handling and press equipment—can further improve productivity. Establish clear color management, QC checkpoints, and ongoing supplier evaluation to maintain quality and consistency at scale, helping you deliver reliable custom gear printing across thousands of pieces without sacrificing brand integrity.

Quality control for UV DTF transfer programs: ensuring durability and consistency

A rigorous quality control regime reduces variability and protects brand value. Implement prepress checks, post-print inspections, and post-press tests (including wash and abrasion testing) on representative fabrics. Document results to refine curing times, temperatures, and pressure, ensuring uniform results as production scales.

Clear care labeling and customer guidance are essential to meeting durability expectations. By communicating proper washing instructions and handling tips, you manage customer experience and preserve print integrity over time. Integrating these practices into your branding messaging can reinforce trust with retailers, distributors, and end customers.

Getting started: a practical playbook to launch UV DTF transfers in your line

Begin with a controlled pilot to validate workflow from design to shipment. Track cycle times, scrap rates, and color accuracy, then translate those metrics into scaling decisions. Building a brand kit with standardized color palettes and placement guides ensures consistency across products and teams as you expand.

Invest in operator training, from design and film handling to heat pressing and QC checks. Track ROI by evaluating costs per unit—ink, film, adhesive, energy—against forecasted sales and margins. Educating customers and partners about the benefits of UV DTF transfers—vibrant color, durability, and fast turnarounds—helps accelerate adoption and supports growth in apparel branding programs.

Frequently Asked Questions

What are UV DTF transfers and how do they support apparel branding?

UV DTF transfers are a direct-to-film transfer using UV-curable inks and a heat-press to apply vibrant, durable images to fabrics. They enable sharp logos and photographic art for apparel branding and custom gear printing, with fast turnaround and scalable production from small runs to large campaigns.

How do UV DTF printing and DTF transfers compare with traditional screen printing for custom gear printing?

UV DTF printing and DTF transfers typically require less setup and allow smaller batch runs than traditional screen printing, while delivering strong color fidelity and smooth gradients. For custom gear printing, they enable rapid prototyping and scalable apparel branding without heavy tooling.

Can UV DTF transfers be used on a wide range of fabrics for scalable textile printing?

Yes. UV DTF transfers work on cotton, blends, and many polyesters, supporting scalable textile printing across diverse product lines. For heat-sensitive fabrics, run a small test to fine-tune curing times and pressure to preserve color and adhesion.

What are the key steps in selecting materials for UV DTF transfers for apparel branding?

Start with UV-curable inks, transfer films, and powders that align with UV DTF transfers for your fabrics. Confirm color management and adhesion compatibility across the fabrics you plan to use, then test heat profiles, verify supplier reliability, and establish a simple prepress and color workflow for consistent apparel branding results.

How can brands scale a UV DTF transfer program while maintaining color fidelity and durability across apparel branding?

Use batch optimization and template-driven workflows to reduce setup and ensure consistent placements. Invest in color management, pilot runs, reliable supplier relationships, and ongoing QC and calibration to maintain color fidelity and durability as you scale UV DTF transfers for apparel branding and custom gear printing.

What are best practices for quality control and post-press care of UV DTF transfers in a scalable textile printing workflow?

Implement a straightforward QC process at prepress, post-press, and final application, including color checks, alignment tests, and edge inspections. Conduct wash and fade tests on representative fabrics, provide care instructions to customers, and document results to guide continuous improvements as you scale UV DTF transfers for scalable textile printing.

| Aspect | Key Points |

|---|---|

| What are UV DTF transfers? |

|

| Why UV DTF transfers matter for business branding on textiles |

|

| The UV DTF printing process: from design to finished gear |

|

| Substrate compatibility and color management for UV DTF transfers |

|

| Equipment, workflow, and supplier considerations for scaling |

|

| Scaling strategies for your custom gear program |

|

| Comparisons: UV DTF transfers vs other methods |

|

| Quality control, durability, and customer expectations |

|

| Practical tips for getting started with UV DTF transfers |

|

Summary

UV DTF transfers offer a powerful path for brands looking to scale custom apparel with confidence. By combining bold color reproduction with a flexible workflow that supports small runs and large batches, UV DTF transfers enable faster turnaround, broader substrate compatibility, and durable, high‑quality prints across product lines. As you scale, focus on a streamlined process, reliable materials, and clear quality controls to preserve brand integrity and deliver consistent value to retailers, distributors, and end customers.