In the world of textile printing, DTF transfer by size is a pivotal aspect that can make or break your printing project. This innovative technology allows for vibrant, high-quality designs to be seamlessly applied to garments, but understanding the nuances of DTF printing sizes is essential for optimal results. Factors such as DTF transfer design considerations and DTF film compatibility necessitate careful planning and execution to prevent costly mistakes. Additionally, mastering heat press settings for DTF plays a crucial role in ensuring that your transfers adhere correctly and maintain their integrity. By focusing on DTF transfer by size, you can significantly enhance your production efficiency and create stunning prints that capture attention.

Direct-to-Film (DTF) transfers have transformed how custom graphics are applied to fabrics, with size being a crucial element in this process. The dimensions of your DTF print can directly affect design layout and material compatibility, making it imperative to understand the optimal sizes for your projects. Various aspects, such as the choice of film, design restrictions, and appropriate heat application techniques, come into play when planning your DTF projects. Furthermore, keeping an eye on the scalability of your transfers can lead to greater production efficiency. This article aims to guide you through the key factors that influence DTF transfers, ensuring that your printing endeavors are not only successful but also tailored to meet the specific demands of your market.

Understanding DTF Printing Sizes

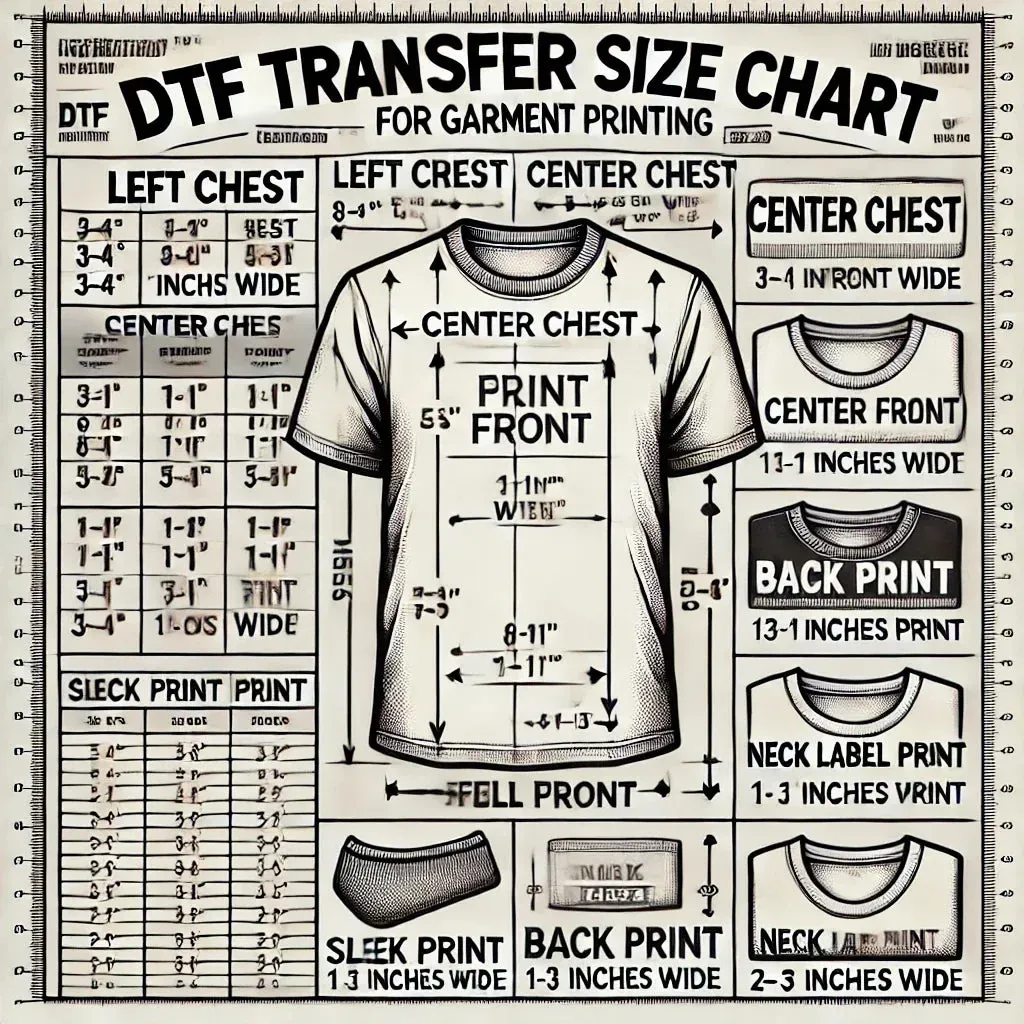

DTF printing sizes are crucial in determining how effectively designs can be transferred onto various fabrics. The size of a DTF transfer directly affects the final output of the print, as well as the material utilization. For instance, when using standard film sizes, it is imperative to match them with the dimensions of the intended garment. Failure to adhere to appropriate sizes may result in wastage of both ink and material. Additionally, understanding the differences in DTF printing sizes can help businesses optimize their workflows, allowing for better planning and reduced costs.

Moreover, different garment types may require varying DTF printing sizes to achieve the desired aesthetic. For instance, a larger transfer might be more suitable for hoodies or jackets, while smaller designs could work better on t-shirts. Designers often have to experiment with different sizes before achieving the perfect balance between impact and compatibility with the fabric. Thus, comprehending DTF printing sizes is key to a successful and efficient printing endeavor.

Critical Design Considerations for DTF Transfers

When creating designs for DTF transfers, several design considerations must be taken into account to ensure quality and effectiveness. One paramount aspect is maintaining appropriate design dimensions that align with the selected DTF film size. Oversized designs can lead to misalignment during the transfer process, complicating the application and possibly detracting from the final product’s appearance. Utilizing design software that allows for size previews can help mitigate such issues by enabling designers to visualize how a design fits within the constraints of the transfer film.

Furthermore, the nature of the design itself plays a significant role in its successful transfer. Complex designs may require more careful consideration when being resized, as scaling can impact intricate details. It is advisable to keep designs clean and bold to avoid loss of quality in smaller sizes while ensuring they remain eye-catching even when resized. These design considerations can significantly enhance the efficiency and quality of DTF transfers.

Evaluating DTF Film Compatibility

DTF film compatibility is another essential factor that has a direct impact on the quality of the final print. Not all films are created equal, and selecting the right type of DTF film is crucial to ensuring successful transfers. It’s imperative to choose films that are specifically designed for the DTF printing process and match the print size requirements of the job. Compatibility here involves ensuring the film can properly adhere to the garment when exposed to heat and pressure.

Additionally, different DTF films may have varying levels of thickness, which can inadvertently affect the transfer outcome. A film that is too thick may not conform well to lightweight fabrics, leading to cracking or peeling, while a film that is too thin may not provide adequate coverage on thicker materials. Thus, evaluating and testing the DTF film’s compatibility with both the intended design and the fabric is vital for achieving desirable results.

Optimizing Heat Press Settings for Various Sizes

The effectiveness of a DTF transfer heavily hinges on the heat press settings employed during application. Larger transfers necessitate specific adjustments to both time and temperature settings, as compared to smaller ones. Careful calibration according to manufacturer guidelines can mean the difference between a durable, high-quality print and one that fades quickly or peels off after washing.

Additionally, variations in heat press settings can yield different adhesion results on various fabric types, suggesting that experiments with different sizes and settings be conducted prior to large-scale production. Maintaining optimal heat press conditions for each transfer size allows businesses to ensure consistent quality and prolongs the life of the garment, demonstrating the importance of this factor in the DTF printing process.

Enhancing DTF Production Efficiency

In the competitive world of textile printing, DTF production efficiency can greatly influence the bottom line. One of the primary ways to enhance efficiency is by strategically selecting DTF transfer sizes based on production volumes. Smaller transfers might allow printers to produce more garments per sheet of film, while larger transfers might require additional film usage, thus increasing costs.

Therefore, understanding how to maximize the number of prints per area while maintaining quality is vital. By analyzing past production runs and experimenting with various sizes, businesses can refine their processes, minimize waste, and ultimately improve profitability. Through these efficiencies, companies can stay competitive while meeting the increasing demand for quality custom prints.

Adapting to Market Trends and Consumer Preferences

As the apparel market evolves, so too do consumer preferences, particularly regarding DTF transfer sizes. Trends indicate a growing inclination towards larger graphics, notably in sectors like streetwear and fashion-forward collections. Businesses keen to thrive in this climate must stay abreast of these trends, ensuring their DTF transfer offerings align with current market demands.

Adapting to these consumer preferences requires careful consideration of how design sizes translate into marketable products. Companies can conduct market research and customer feedback sessions to determine the types of designs and sizes that resonate most with their target audience. This approach not only ensures relevance but also aids in creating products that stand out in a saturated marketplace.

Frequently Asked Questions

What are the key considerations for DTF transfer by size?

When working with DTF transfer by size, consider the film compatibility with the garment, design constraints, material thickness and texture, heat press settings, production efficiency, and current market trends. Each of these factors can significantly affect the print quality and overall efficiency of the transfer process.

How do DTF printing sizes affect the print quality?

DTF printing sizes are critical, as the size of the transfer film must match the garment dimensions. If the size is incorrect, it can lead to misalignment, wasted materials, and a poor-quality print. Ensuring proper sizing will enhance adhesion and visual appeal.

What design considerations should I keep in mind for DTF transfers?

When designing for DTF transfers, it’s essential to ensure that the design fits within the size limits of the transfer film. Oversized graphics can lead to distortions and longer print times. Utilize design software to preview the size specifications before printing.

How do heat press settings change according to DTF transfer size?

Heat press settings must be adjusted based on the size of the DTF transfer. Larger transfers usually require specific temperatures and pressing times to achieve proper adhesion. Always refer to the manufacturer’s guidelines for the best results.

What is the importance of material thickness in DTF transfers by size?

Material thickness impacts the size of the DTF transfer necessary for effective application. Thicker fabrics may require larger transfers for complete coverage and adhesion, while thinner materials can accommodate smaller transfers without compromising quality.

How can businesses improve DTF production efficiency through transfer sizing?

Businesses can enhance DTF production efficiency by choosing optimal transfer sizes that maximize the number of prints per film sheet. Smaller transfers generally lead to reduced material waste and shortened processing times, ultimately lowering production costs.

| Factor | Description |

|---|---|

| Film Size and Compatibility | The size of the transfer film must match the dimensions of the garment for optimal quality. Misalignment can lead to wasted materials and increased costs. |

| Design Considerations | Graphics should align with film size constraints to avoid distortion and extended printing times. Design tools can assist in previews. |

| Material Thickness and Texture | Different fabrics require specific transfer sizes. Thicker materials need larger transfers for proper coverage, while thinner fabrics can use smaller ones. |

| Heat Press Settings | Larger transfers have different heat and time requirements compared to smaller ones. Adhering to guidelines is vital for adhesion and longevity. |

| Scalability and Production Efficiency | Transfer size impacts production efficiency. Optimally sized transfers can help reduce costs and increase print quantities without sacrificing quality. |

| Market Trends and Consumer Preferences | Staying current with size trends in consumer graphics, especially in streetwear, helps businesses adapt and remain competitive. |

Summary

DTF Transfer by Size is a crucial topic for anyone involved in textile printing, as it highlights the importance of understanding the various factors that affect print quality and production efficiency. By carefully considering aspects such as film compatibility, design limitations, material properties, heat settings, scalability, and market trends, businesses can leverage DTF technology to produce stunning prints that meet consumer demands. Mastering these factors is essential for achieving success in the competitive world of apparel printing.