DTF transfer by size is a pivotal concept in the realm of custom garment printing, ensuring that designs not only fit but also resonate aesthetically on various fabrics. As the popularity of DTF printing grows, understanding the nuances of size adjustment techniques becomes essential for achieving vibrant and impactful results. DTF technology allows creators to print intricate designs that can be perfectly tailored to any garment size, from tiny accessories to oversized apparel. This guide will delve into the importance of size in DTF transfers, covering aspects such as material considerations and the overall process of printing textiles. Mastering the sizing of DTF transfers will elevate the quality of your printed products and enhance customer satisfaction.

When it comes to Direct-to-Film transfer, also known as DTF printing, the intricacies of size become a critical component for producing quality prints on apparel. Utilizing various size adjustment methods, businesses can create an array of custom designs that cater to diverse market demands. This modern printing technique not only enables precise detail but also ensures that visual impact is maintained, regardless of the garment’s dimensions. It’s crucial to consider both the design’s scaling techniques and the choice of substrate when embarking on a DTF printing journey, as these factors contribute significantly to the final appearance of the textiles. By honing in on these aspects, creators can guarantee that their prints deliver exceptional results across different styles and materials.

Understanding DTF Transfer Technology

Direct-to-Film (DTF) printing technology has revolutionized the custom garment printing industry by offering unparalleled versatility and high-quality results. This innovative method involves printing designs onto a specialized film before transferring them onto various textiles, making it a preferred choice for many businesses. With its ability to produce vibrant colors and intricate details, DTF printing stands out compared to traditional methods like screen printing, which often lacks the finesse that comes with DTF technology.

Additionally, DTF transfers are compatible with multiple fabric types, including cotton and polyester, providing endless possibilities for customization. Since the designs are applied as a transfer, the final product maintains a soft feel, enhancing the overall wearing experience. Understanding how DTF printing works lays the foundation for exploring further intricacies, such as how to optimize size for the best visual outcomes on garments.

Frequently Asked Questions

What is DTF transfer by size and why is it important?

DTF transfer by size refers to the specific measurements and adjustments made to Direct-to-Film designs to ensure they fit perfectly on the chosen garment. This aspect is crucial because the size of the transfer influences the overall aesthetic and visibility of the design, affecting customer satisfaction and product appeal.

How do size adjustment techniques impact DTF printing?

Size adjustment techniques in DTF printing are essential for maintaining the integrity and visual appeal of designs. By scaling designs accurately and preserving their aspect ratio, printers ensure the final product looks professional and attractive, preventing distortion that could diminish the quality of the garment.

What materials work best with DTF transfers by size?

Materials like 100% cotton and polyester blends are ideal for DTF transfers by size. Their compatibility with the printing process ensures vibrant colors and proper adhesion of the ink, which are crucial for achieving high-quality custom garment printing.

Can DTF technology accommodate large designs with size adjustments?

Yes, DTF technology can accommodate large designs. Many wide-format DTF printers can handle designs up to 24 inches wide, allowing for significant size adjustments while maintaining high resolution. This is beneficial for businesses aiming to produce larger custom prints.

What challenges might arise with DTF transfer by size and how can they be addressed?

Challenges in DTF transfer by size include inconsistencies across batches caused by printer calibration and material changes. To mitigate these issues, regular printer calibration and thorough pre-print checks are recommended to ensure uniform quality and accurate size adjustments.

How has the demand for custom sizing affected DTF printing trends?

The growing demand for personalized apparel has led to a surge in custom sizing services within DTF printing. This trend allows businesses to offer tailored options that meet individual customer expectations, enhancing satisfaction and loyalty to their brand.

| Key Points | Details |

|---|---|

| Introduction to DTF Transfer | DTF transfer is a versatile printing technology for customized designs on various fabrics. |

| Process of DTF Transfer | Involves printing on film, applying adhesive, and heat pressing onto fabric. |

| Importance of Sizing | Correct sizing affects aesthetics and final product quality. |

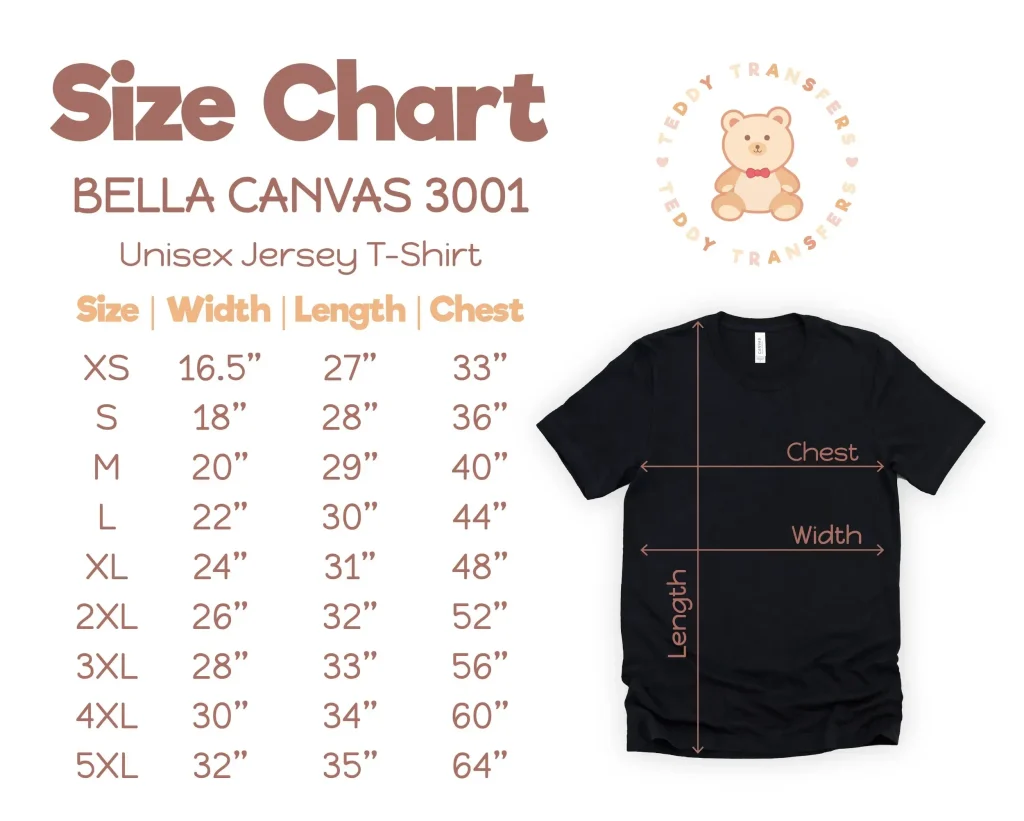

| Techniques for Size Adjustment | Scaling designs, maintaining aspect ratio, understanding printer specs. |

| Material Considerations | Material thickness and color influence visibility and sizing needs. |

| Recent Trends | Larger format printers and custom sizing services on the rise. |

| Challenges and Solutions | Maintain consistency with printer calibration and pre-print checks. |

| Scalability in Production | Able to adjust sizes seamlessly for various applications. |

Summary

DTF transfer by size is fundamental in producing high-quality prints that meet customer expectations. To achieve optimal results, understanding the intricacies of sizing, material considerations, and the printing process is essential. As technology progresses, the advantages of DTF printing become increasingly apparent, allowing for customized designs that are both vibrant and precise. By focusing on the relationships between size, fabric type, and printing techniques, businesses can cater to a broader clientele, enhancing their brand’s presence in the market. Embracing these elements not only boosts product quality but also fosters customer satisfaction, crucial for long-term success in the textile printing industry.