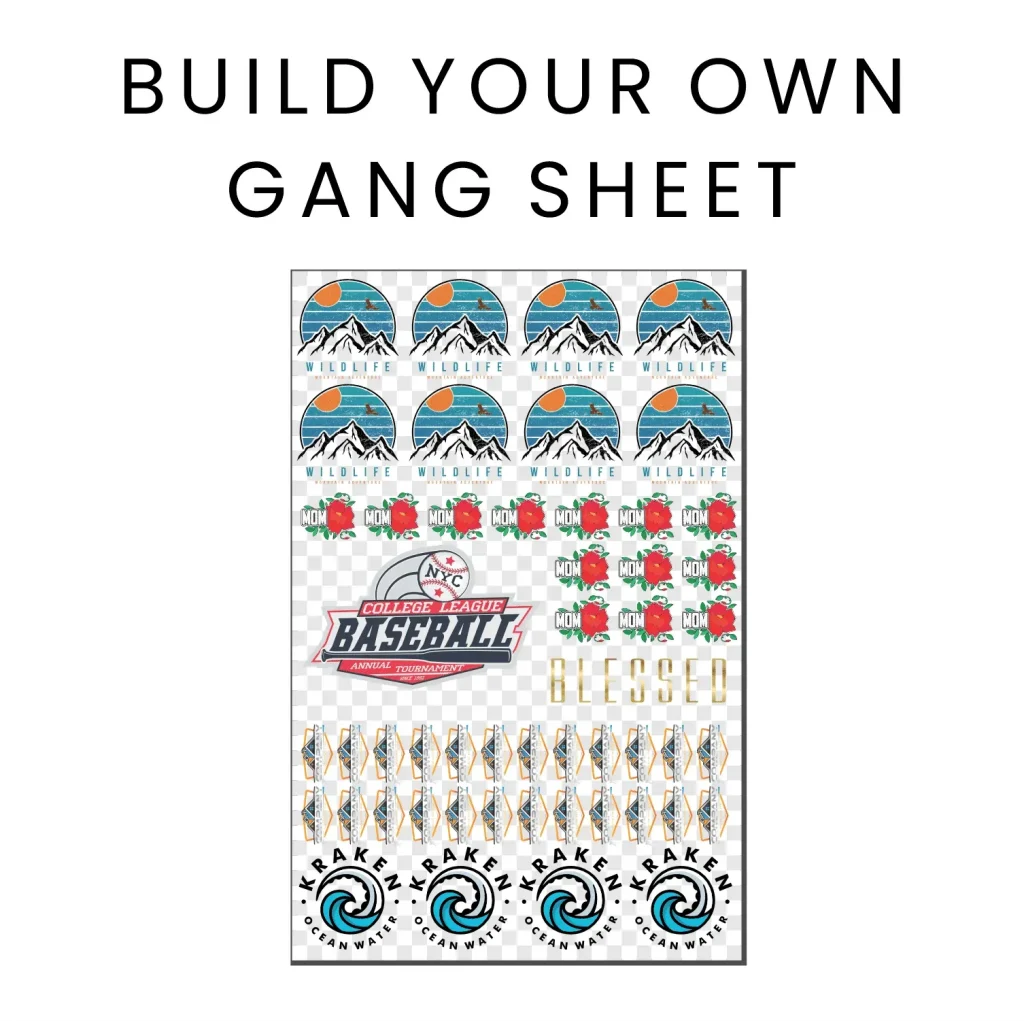

The DTF Gangsheet Builder is transforming the realm of Direct Transfer Film (DTF) printing by enabling users to design and print multiple images on a single sheet. This innovative tool not only boosts productivity but also minimizes material waste, making it a must-have for both small businesses and large-scale operations. By mastering the ins and outs of the DTF Gangsheet Builder, users can craft stunning designs while ensuring optimal efficiency. Furthermore, understanding DTF printer settings and post-processing techniques can greatly enhance the quality of your prints. Dive into these **5 essential tips** for using the DTF Gangsheet Builder effectively and elevate your DTF printing game to the next level.

The DTF Gangsheet Builder, a groundbreaking tool in the landscape of digital garment printing, allows for the simultaneous creation of multiple designs on one transfer sheet. Leveraging this functionality not only sharpens operational efficiency but also curtails material wastage, aligning perfectly with contemporary eco-friendly practices. To fully harness the power of this builder, it’s imperative to grasp the nuances of layout design for DTF as well as the intricacies involved in DTF transfer film compatibility. Mastering DTF printer configurations and post-printing processes is equally crucial to ensuring vibrant, long-lasting results. This guide presents essential insights to optimize your usage of the DTF Gangsheet Builder and successfully navigate the DTF printing workflow.

Understanding the Basics of DTF Printing

DTF printing has quickly gained traction in the textile industry due to its flexibility and impressive results. This innovative method utilizes specialized transfer films to allow vibrant, high-quality prints on a range of materials, from cotton to polyester blends. The versatility of DTF printing makes it ideal for custom apparel, promotional items, and even intricate designs that traditional methods struggle to achieve.

A crucial component of DTF printing is the DTF Gangsheet Builder, which lets users maximize the use of space on each print sheet. By strategically placing multiple designs on a single sheet, production efficiency increases, reducing overall material waste. Understanding the fundamentals of DTF technology sets the stage for implementing best practices that enhance the printing process.

Choosing Quality DTF Transfer Film

One of the most significant determinants of print quality in DTF printing is the choice of DTF transfer film. High-quality films ensure that ink adheres properly and provides durability that stands up against wear and washing. Investing in reputable brands not only enhances the vibrancy of colors but also minimizes issues related to peeling or cracking over time.

Additionally, pairing the right film with corresponding inks can lead to a significant improvement in the final product. As businesses strive to produce high-quality prints that meet customer expectations, considering the compatibility of transfer films with various DTF printer settings is crucial for achieving consistent results.

Maximizing Your Design Layout for Efficiency

Creating an effective design layout is vital for maximizing the potential of the DTF Gangsheet Builder. Using graphic design software, users can arrange multiple designs on a single sheet, ensuring every inch of space is used wisely. This thoughtful layout not only helps in optimizing the number of prints per sheet but also reduces time spent on trimming and preparing each design before the print cycle.

A well-organized gangsheet layout can also improve the quality of the final product. Arranging designs with a strategic approach, such as avoiding overlapping or leaving sufficient spacing, ensures that each design receives equal attention during the printing process, which is essential for achieving high-resolution results, especially when utilizing intricate designs.

Importance of Conducting Test Prints

Before launching into full-scale production, conducting test prints is crucial in the DTF printing process. Test prints allow for the calibration of printer settings and serve as a preliminary assessment of the print quality and material compatibility. This step is invaluable, as it helps identify potential issues such as color matching and ink saturation that may not be evident until after bulk production begins.

Moreover, utilizing test prints facilitates experimentation with different DTF printer settings to find the optimal configuration that yields the highest quality output. Adjusting temperature, speed, and ink flow based on test results ensures that the final products meet or exceed customer expectations while minimizing waste.

Adjusting Printer Settings for Optimal Output

Fine-tuning your printer settings is a critical aspect of optimizing DTF printing results. Each type of DTF transfer film may require different settings on the DTF printer, including temperature adjustments and ink saturation levels. Understanding how these variables interact with different materials is essential for producing quality prints that adhere effectively and maintain vibrancy.

Additionally, learning about your printer’s capabilities and limitations can empower users to document and adjust settings systematically. This knowledge allows for quick adaptations when introducing new materials or films, ensuring efficient operation without sacrificing quality.

Effective Post-Processing Techniques for DTF Prints

Post-processing is an essential phase in the DTF printing workflow that directly affects the longevity and quality of the prints. Techniques such as proper curing processes ensure that the ink adheres firmly to the substrate, preventing peeling or fading over time. Depending on the specific DTF transfer film in use, different curing methods may yield varied results, making it vital for users to follow best practices.

Moreover, thorough post-processing isn’t limited to curing alone—effective peeling techniques also play a pivotal role in the overall outcome. By allowing prints to cool down adequately before removal or using specialized tools for peeling, users can enhance the durability of their prints, leading to satisfied customers and reduced returns.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how does it work?

The DTF Gangsheet Builder is a specialized tool designed for creating multiple designs on a single Direct Transfer Film (DTF) sheet. This tool optimizes the layout of designs to maximize space usage, allowing for efficient printing and reduced waste. By utilizing the DTF Gangsheet Builder, users can streamline their workflow, saving time and resources while still producing high-quality prints.

How do I choose the right materials for DTF printing?

Selecting high-quality DTF transfer film and appropriate inks is crucial for successful DTF printing. Quality materials enhance the vibrancy and durability of your prints, ensuring compatibility with your DTF printer settings. Investing in the right materials minimizes the risk of print failures and helps maintain cost efficiency by reducing reprints and waste.

What are best practices for optimizing design layouts for DTF prints?

To effectively maximize available space on your DTF gangsheet, it’s important to use graphic design software to arrange your designs. Avoid cutoff areas by creating a thoughtful layout, and utilize vector files for high-resolution outputs. Proper optimization ensures that every inch of the DTF Gangsheet is used efficiently, leading to superior print results.

Why is it important to conduct test prints when using the DTF Gangsheet Builder?

Conducting test prints is essential for calibrating your DTF printer settings and materials before bulk production. This practice allows you to identify potential issues and make necessary adjustments, ensuring high-quality outputs with fewer problems during the final print run. It ultimately leads to improved efficiency and results in your DTF printing projects.

How do I adjust DTF printer settings for optimal results?

Adjusting your DTF printer settings is critical for achieving quality prints with the DTF Gangsheet Builder. This includes fine-tuning settings such as temperature and ink flow based on the specific characteristics of the DTF transfer film being used. Proper calibration enhances adherence and print quality, maximizing the effectiveness of each print.

What post-processing techniques should I use after DTF printing?

Post-processing techniques, such as curing and peeling, are vital for ensuring the longevity and quality of your DTF prints. Adhere to recommended curing times and methods to guarantee that prints bond effectively with the fabric. Implementing these post-processing best practices minimizes issues and maximizes the durability of your designs.

| Key Points | Description |

|---|---|

| Understanding DTF Technology | DTF printing uses special film for versatile designs across materials, enhancing production workflows with tools like the DTF Gangsheet Builder. |

| Tip #1: Choosing the Right Materials | Use high-quality DTF transfer film and inks to ensure durability and reduce print failures. |

| Tip #2: Optimize Design Layout | Utilize graphic design software to maximize the use of space on gang sheets, preventing cut-offs. |

| Tip #3: Conduct Test Prints | Perform test prints to calibrate settings and assess different materials before bulk production. |

| Tip #4: Adjust Printer Settings | Fine-tune printer settings based on the media to enhance print quality and adherence. |

| Tip #5: Post-Processing Techniques | Employ proper curing and peeling methods to ensure prints last and maintain quality over time. |

Summary

DTF Gangsheet Builder offers a comprehensive approach to improving your printing projects through effective use of technology. Understanding the DTF printing process is vital in maximizing productivity, and implementing the right strategies can lead to impressive results. By focusing on quality materials, optimizing designs, conducting tests, adjusting settings, and mastering post-processing, users can achieve high-quality outputs that stand out. Embracing these five essential tips will not only enhance your workflow with the DTF Gangsheet Builder but also elevate your print quality in an increasingly competitive market.