DTF gangsheet builder features are redefining how shops plan and execute transfers for apparel, combining design, tiling, color control, and export into a single streamlined workflow. As a cornerstone of the DTF printing workflow, these tools help you maximize sheet utilization and maintain color fidelity across runs. A strong option also functions as DTF gangsheet software and a gangsheet maker for DTF, delivering built-in DTF design templates that speed up production. With templates, intelligent tiling, and accurate color management, you can reduce waste and scale from small orders to high-volume runs. This introductory guide highlights the top features to look for and how they translate into real-world efficiency and profitability.

In plain terms, this kind of sheet-assembly tool acts as a transfer sheet layout engine that consolidates artwork, spacing, and color management into a single printable plan. Think of it as a template-driven design library and a print-ready pipeline that translates artwork into efficient gangsheet grids across multiple garment sizes. From an LSI perspective, related concepts include transfer printing workflow optimization, template ecosystems, and cloud-enabled collaboration to maintain consistency across runs. By focusing on semantically related terms like color validation, ICC profiles, and tiling automation, shops can discover compatible solutions that fit their RIPs and printers.

DTF Gangsheets and Production Efficiency: Maximizing Output with Smart Layout and Tiling

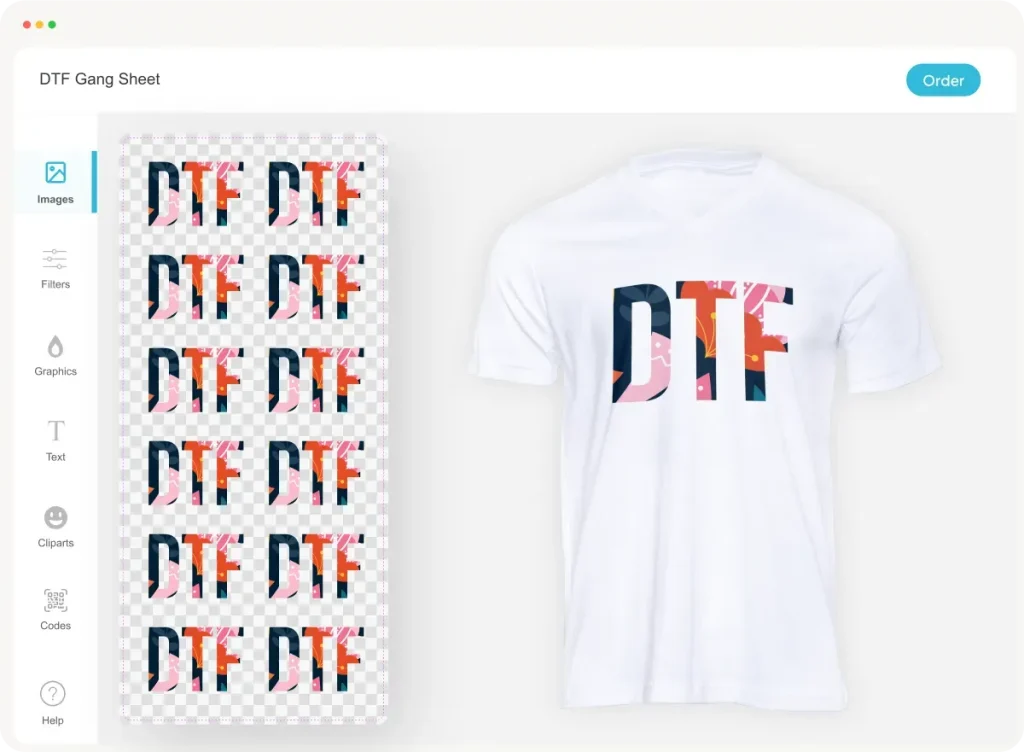

DTF gangsheet software enables bulk layout and tiling that maximizes sheet utilization. By automatically tiling designs with smart spacing, bleed, and margins, shops can cut waste and speed up the setup phase. Real-time guides, snap-to-grid, and alignment cues help maintain consistent margins across shirts, bags, and accessories, even when juggling multiple sizes on a single sheet. When paired with a streamlined DTF printing workflow, this capability reduces manual errors and accelerates initial layout time.

Using a proven gangsheet maker for DTF and leveraging ready-to-use DTF design templates further reinforces efficiency. Templates provide repeatable layouts for popular product families, ensuring brand consistency and predictable margins. This synergy between smart layout tools and design templates translates into faster production, fewer reworks, and more predictable throughput, especially during seasonal campaigns.

Achieving Color Confidence: Accurate Color Management for DTF Printing

Color fidelity starts with integrated color management in the DTF gangsheet software. ICC profiles, soft-proofing, and pre-visualization help operators see how transfers will appear on actual substrates before printing, reducing color surprises. A color-aware DTF printing workflow keeps previews aligned with the final transfers, even when switching between dark fabrics and bright textiles, by testing color relationships on-screen and adjusting accordingly.

Embedding profiles in export files and enabling substrate color simulation minimizes mismatches and waste. Staff can standardize color workflows across teams, ensuring consistent results from the first design to the last transfer. By focusing on accurate color management, shops protect brand integrity and customer satisfaction across order volumes.

DTF Design Templates: Fast Tracks to Consistent Layouts

DTF design templates form the backbone of rapid, repeatable production. A robust template library lets designers reuse proven layouts, swap in new artwork, and maintain safe margins and bleed for apparel and accessories. This capability accelerates the move from design to print and supports brand consistency across collections, especially when high-volume runs demand predictable output.

A well-curated set of DTF design templates also reduces the learning curve for new staff and minimizes error when collaborating in a team. Combined with a reliable gangsheet maker for DTF and a compatibility-focused DTF gangsheet software, templates help you scale from pilot runs to full production without sacrificing quality.

DTF Gangsheet Builder Features: End-to-End Workflow Acceleration

DTF gangsheet builder features encompass the core tools that accelerate the entire pre-press to print pipeline. An intuitive drag-and-drop interface, real-time preview, and collision detection let operators layout designs, detect overlaps, and verify margins before sending files to RIP software. These capabilities directly support the DTF printing workflow by reducing setup time and preventing costly misprints.

Beyond layout, these features include robust export options, embedded color profiles, and seamless RIP integration that align with the gangsheet maker for DTF ecosystem. When teams leverage this end-to-end toolset, production becomes more repeatable, scalable, and resilient to bottlenecks during peak seasons.

Multi-Sheet and Multi-Size Flexibility for Custom Runs

Many DTF orders require multiple sizes within a single production run. A capable DTF gangsheet builder supports multi-sheet layouts, variable data fields, and multiple sizes per print plan, enabling a single gangsheet to serve a family of garments. This flexibility minimizes make-ready time and keeps production aligned with demand, while reducing waste across different sizes.

A strong toolchain for multi-size layouts also helps with promotional campaigns and seasonal drops. By planning several sizes in one project, teams can maintain color consistency and layout integrity across variants and ensure that RIP software can handle the final export without manual rework. This is where the synergy of DTF gangsheet software, gangsheet maker for DTF, and DTF design templates shines.

Collaboration, Cloud Sync, and RIP Integration in the DTF Workflow

In modern shops, cloud syncing, version control, and collaborative commenting are essential. A DTF printing workflow that includes these collaboration features keeps designers, pre-press, and operators aligned, reduces file conflicts, and speeds approvals. Version history and permission controls protect templates and archived projects, so teams can reuse successful gangsheet configurations in future runs.

Additionally, seamless integration with RIP software and printer workflows ensures that export formats, ICC profiles, and bleed settings land correctly in production. When you combine cloud-based collaboration with robust RIP integration, you gain predictable throughput and faster onboarding for new team members, boosting overall efficiency and profitability.

Frequently Asked Questions

How do DTF gangsheet builder features optimize the DTF printing workflow?

DTF gangsheet builder features streamline the DTF printing workflow by enabling rapid layout, precise tiling, and color-accurate output. Core capabilities include an intuitive drag-and-drop interface, bulk layout and tiling to maximize sheet utilization, ICC-based color management with soft-proof previews, a built-in DTF design templates library, and print-ready export options that align with your RIP software. Together, these features reduce setup time, minimize waste, and maintain consistent transfers across runs.

What impact does the intuitive drag-and-drop interface have in a DTF gangsheet software for speed and accuracy?

The intuitive drag-and-drop interface lets designers place, resize, and align designs quickly with real-time guides, snap-to-grid, and alignment cues, reducing training time and preventing overlaps when juggling multiple sizes or orientations. This is especially valuable when using DTF design templates to maintain consistent margins and bleed.

How do DTF design templates contribute to consistency in a gangsheet maker for DTF?

DTF design templates speed the design-to-print cycle and ensure consistent margins, bleed, and branding across runs. A robust template library lets you reuse proven layouts, swap artwork, and preserve alignment with existing gangsheet configurations, improving efficiency within the DTF printing workflow.

Why is color management and ICC profile support essential in a DTF gangsheet builder?

Color management with ICC profiles provides a color-accurate preview and embedded profiles in exports, reducing mismatches between on-screen proofs and final transfers. Soft-proofing and substrate color simulations help you maintain consistent color fidelity across apparel transfers, a critical part of the DTF printing workflow.

How do cloud syncing and collaboration features enhance a gangsheet maker for DTF in a team environment?

Cloud syncing and version history keep teams aligned, allow concurrent editing, and protect templates and projects. Clear permissions and centralized storage shorten onboarding and speed up iteration across designers, pre-press, and production, improving the DTF printing workflow in multi-person environments.

What export and integration features should you look for in a DTF gangsheet software to ensure print-readiness?

Look for multiple export formats (PDF, PNG, TIFF) with embedded ICC profiles, correct DPI, bleed, and RIP-friendly exports. Native project files and automation hooks, plus seamless integration with RIP software and printers, reduce post-processing and keep the DTF printing workflow smooth from design to production.

| Feature | Key Points |

|---|---|

| Feature 1: Intuitive drag-and-drop interface for rapid layout | Place, resize, rotate and align designs quickly using real-time guides and snap-to-grid. A clean UI reduces training time and speeds up production, with alignment cues to prevent overlaps and wasted space, even when juggling multiple sizes and orientations. |

| Feature 2: Bulk layout and tiling tools to maximize sheet utilization | Auto-tile designs across a sheet, optimize spacing, and predefine bleed margins. Reduces waste and manual errors; supports auto reflow on edits and smart gaps, and can mix multiple sheet sizes in one print plan. |

| Feature 3: Accurate color management and ICC profile support | Color accuracy is ensured with ICC profiles, soft-proofing, and embedded color profiles. Preview color-accurate results before print and simulate substrate color changes to reduce on-press mismatches. |

| Feature 4: Built-in template library and DTF design templates | Library of templates and design elements tailored to apparel sizes. Reuse proven layouts, maintain margins and bleed, and preserve brand consistency across runs. |

| Feature 5: Flexible export options and print-readiness | Multiple export formats (PDF, PNG, TIFF, native project files) and presets. Embedded color profiles, correct DPI, bleed settings, and print-ready exports reduce post-processing and handoffs. |

| Feature 6: Real-time preview, collision detection, and error checking | Live previews with color overlays and layout fidelity. Collision detection prevents overlaps; built-in checks for missing assets, fonts, or low-res graphics catch issues before RIP. |

| Feature 7: Multi-sheet, multi-size, and multi-layout support | Supports multiple sheets and sizes per job, variable data fields, and diverse layouts within a single project. Reduces complexity and keeps orders efficient. |

| Feature 8: Cloud syncing, collaboration, and version control | Version history, permissions, and concurrent editing for teams. Cloud storage protects templates and enables reuse of successful configurations across runs. |

| Feature 9: Licensing, pricing options, and offline access | Transparent licensing, scalable tiers, and offline work capability. Clear pricing supports budgeting and ROI considerations as you scale. |

| Feature 10: Seamless integration with RIP software and printer workflows | Exports are compatible with major RIPs, ICC profiles are supported, and options for direct-to-cut/transfer. Automation hooks and integrations streamline print workflows. |